LC vs SC Fiber Optic Connectors

In the world of fiber optic networking, connector selection might seem like a minor detail, but it can significantly impact network performance, scalability, and maintenance costs. Two of the most prevalent connector types dominating the market are LC (Local Connector or Little Connector) and SC (Subscriber Connector or Square Connector). Understanding the differences between these two standards is essential for network engineers, IT professionals, and even home networking enthusiasts.

Table of Contents

What Are Fiber Optic Connectors?

Fiber optic connectors join fiber optic cables together or connect them to equipment. Think of them as specialized plugs that carry light signals instead of electricity.

Unlike electrical connections, where close is good enough, fiber connections must be perfectly aligned. Even tiny misalignments can cause big problems with your network.

Quick Fact: The glass core in a typical single-mode fiber is just 9 microns wide – that’s about 1/10 the width of a human hair!

SC Connectors: The Square Connector

SC (Subscriber Connector or Square Connector) features a distinctive square shape that has earned it the nickname “square connector.”

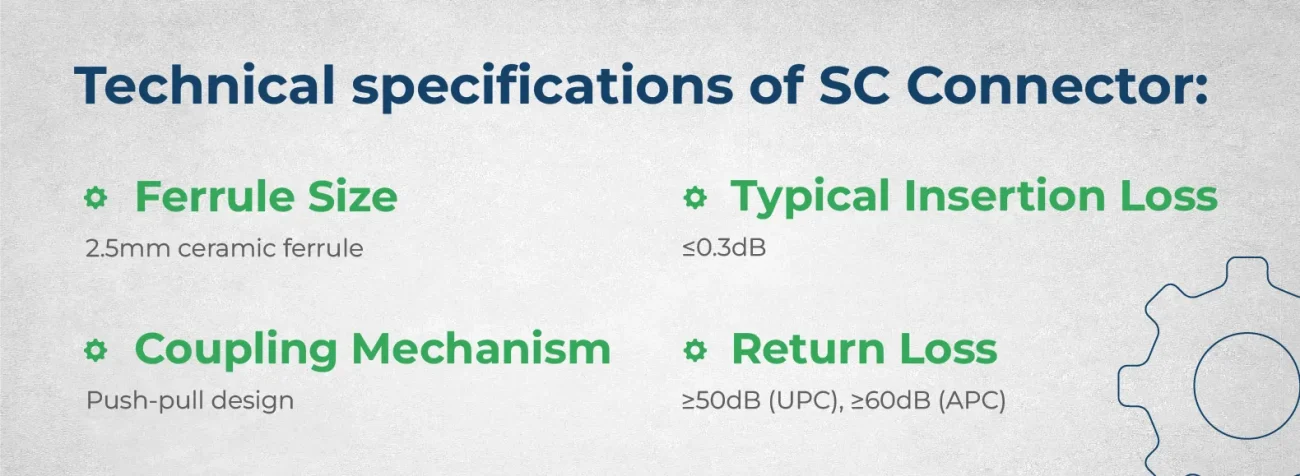

Here are the key technical specifications:

- Ferrule Size: 2.5mm ceramic ferrule

- Connector Size: Approximately 8.99mm × 9.89mm × 29.25mm

- Coupling Mechanism: Push-pull design

- Polish Types Available: UPC (Ultra Physical Contact) and APC (Angled Physical Contact)

- Typical Insertion Loss: ≤0.3dB

- Return Loss: ≥50dB (UPC), ≥60dB (APC)

- Standards Compliance: TIA/EIA-568, IEC 61754-4

The SC connector follows a simple push-pull design principle. The connector body slides into the adapter until it clicks into place, requiring no twisting motion. This straightforward coupling mechanism reduces the risk of damage to the fiber during connection and disconnection cycles.

Real-world example: SC connectors are common in fiber-to-the-home installations, where technicians might need to make connections while wearing gloves or in poor lighting conditions.

Applications and Use of SC

SC connectors excel in several specific scenarios:

Telecommunications Infrastructure Many telecommunications providers standardized on SC connectors for their central office and field installations. The robust design withstands the challenging environmental conditions often encountered in these settings.

Passive Optical Network (PON) SC connectors are commonly used in Fiber-to-the-Home (FTTH) deployments and other PON applications. Their durability and straightforward installation characteristics make them suitable for scenarios where connections may be managed by individuals with varying levels of technical expertise.

Test and Measurement Equipment Test instruments frequently feature SC connector interfaces due to their durability and reliable performance. The larger connector size is less likely to be damaged during frequent connect/disconnect cycles typical in testing scenarios.

Educational Environments Technical schools and training facilities often prefer SC connectors for their visibility and ease of handling, making them ideal for teaching proper fiber handling and connection techniques.

LC Connectors: The Little Connector

LC stands for “Lucent Connector.” LC (Local Connector or Little Connector) represents a significant advancement in connector miniaturization.

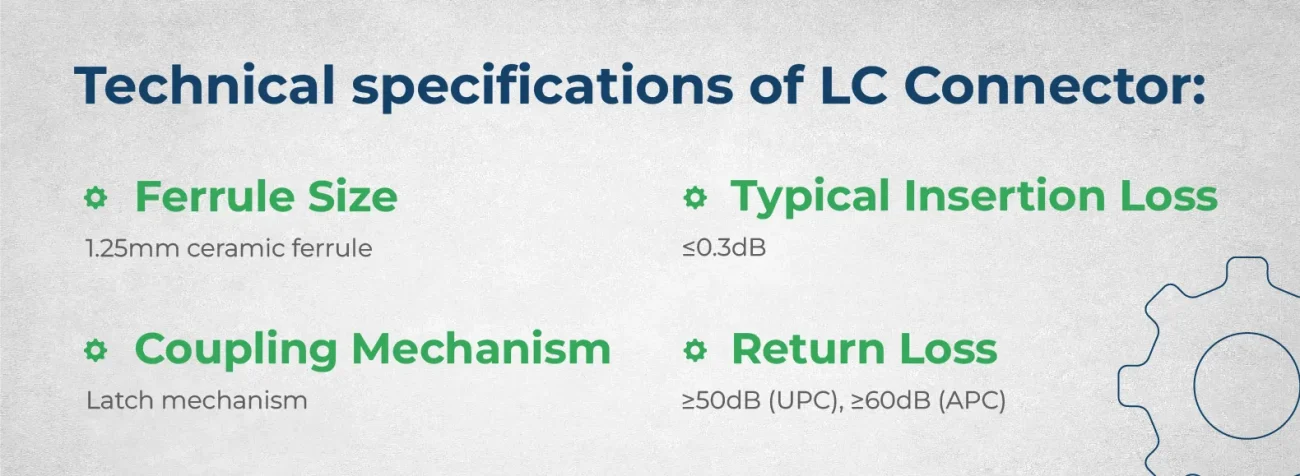

Here are its key technical specifications:

- Ferrule Size: 1.25mm ceramic ferrule

- Connector Size: Approximately half the size of SC connectors

- Coupling Mechanism: Latch mechanism similar to RJ-45 connectors

- Polish Types Available: UPC (Ultra Physical Contact) and APC (Angled Physical Contact)

- Typical Insertion Loss: ≤0.3dB

- Return Loss: ≥50dB (UPC), ≥60dB (APC)

- Standards Compliance: TIA/EIA-568, IEC 61754-20

The distinctive latch mechanism of LC connectors resembles the familiar RJ-45 connector used in copper Ethernet networks. This design provides secure retention while allowing easy disconnection by pressing the release tab.

Real-world example: Most modern network switches, routers, and servers use LC connectors because manufacturers can fit more ports on their equipment.

Applications and Use Cases of LC

LC connectors dominate in several key areas:

Enterprise Networks and Data Centers The high density and compatibility with modern equipment make LC connectors the standard choice for enterprise networks and data centers. The space savings translate directly into more efficient use of rack space and improved airflow.

Transceivers and Active Equipment SFP, SFP+, QSFP, and similar optical transceiver formats almost exclusively use LC interfaces. As these transceivers have become ubiquitous in networking equipment, LC connectors have become the de facto standard.

High-Density Patch Panels LC connectors enable significantly higher port counts in fiber patch panels. A standard 1U rack panel can accommodate up to 96 LC connections compared to only 48 SC connections.

Mobile and Remote Equipment The smaller size and secure latch mechanism make LC connectors ideal for mobile and remote equipment where space is constrained, and connections must remain secure despite movement or vibration.

5 Key Differences Between LC vs SC Fiber Optic Connectors

1. Size and Density

The physical size difference between SC and LC connectors has significant implications for network design and scalability:

Footprint Comparison:

- SC connector: Approximately 9mm × 10mm footprint

- LC connector: Approximately 4.5mm × 10mm footprint

This size difference means LC connectors provide twice the density of SC connectors in the same space. For perspective, a standard 1U rack-mount patch panel can accommodate:

- Up to 48 SC duplex ports (96 fibers)

- Up to 96 LC duplex ports (192 fibers)

2. Insertion Loss and Return Loss Values

When properly installed, both LC and SC connectors deliver comparable optical performance:

Insertion Loss (lower is better):

- SC connectors: Typically ≤0.3dB

- LC connectors: Typically ≤0.3dB

Return Loss (higher is better):

- SC UPC: ≥50dB

- LC UPC: ≥50dB

- SC APC: ≥60dB

- LC APC: ≥60dB

While the specified performance values are similar, real-world experience suggests subtle differences:

- The larger 2.5mm ferrule of SC connectors sometimes provides slightly better alignment stability over time.

- The smaller 1.25mm ferrule of LC connectors requires more precise manufacturing but can achieve comparable performance with modern production techniques.

A study by the Fiber Optic Association found that both connector types maintain performance well within industry standards when properly installed and maintained, with negligible differences in practical applications.

3. Durability and Maintenance

Mating cycle ratings measure connector durability, or how many times they can be connected and disconnected before performance degrades:

Mating Cycle Durability:

- SC connectors: Typically rated for 1,000+ mating cycles

- LC connectors: Typically rated for 500-1,000 mating cycles

The difference in durability stems primarily from the connector designs:

- SC’s larger size and push-pull mechanism distribute stress more evenly.

- LC’s latch mechanism places more stress on the small plastic tab, which can wear or break with extensive use.

Environmental Testing: Both connector types perform well in standard environmental tests covering temperature extremes, humidity, and vibration. However, SC connectors often demonstrate slight advantages in harsh environments due to their more robust construction.

For networks with frequent reconfiguration requirements or testing environments, SC connectors may offer longer service life. For stable installations with minimal changes, both connector types provide excellent longevity.

4. Cost Comparison

Price Differences:

- SC connectors: Generally $2-5 each

- LC connectors: About $3-7 each

- Patch cables: LC cables typically cost 10-20% more than equivalent SC cables

Why the Price Difference? LC connectors cost more because they’re smaller and require more precise manufacturing. However, the price gap has narrowed as LC connectors have become more common. Discover more

Budget Tip: For large projects, the cost difference between connector types can add up. For 1,000 connections, LC might cost $1,000-2,000 more than SC.

5. Equipment Compatibility

- LC: Standard on most modern equipment (servers, switches, routers)

- SC: Common in older equipment and telecom installations

The Trend: Equipment manufacturers have overwhelmingly standardized on LC connectors for new products. If you’re buying new equipment, it probably uses LC.

Choosing Between LC and SC: Decision Guide

Choose LC Connectors When:

- You need to fit many connections in a small space

- You’re connecting to modern networking equipment

- You’re building a data center or server room

- Future expansion might require more connections in the same space

Choose SC Connectors When:

- Ease of handling is more important than space savings

- You’re working in harsh environments or outdoor installations

- Your technicians find larger connectors easier to work with

- You’re extending or maintaining a network that already uses SC

Quick Reference Chart: LC vs SC at a Glance

| Feature | LC Connector | SC Connector |

| Size | Small (half the size of SC) | Larger, square shape |

| Density | High (2× connections in same space) | Standard density |

| Connection style | Latch mechanism (like phone plug) | Push-pull mechanism |

| Ferrule size | 1.25mm | 2.5mm |

| Typical use | Data centers, modern equipment | Telecom, older equipment |

| Ease of handling | Can be fiddly, especially with gloves | Easier to handle |

| Durability | Good (500-1,000 mating cycles) | Better (1,000+ mating cycles) |

| Cost | Slightly higher | Slightly lower |

| Future-proofing | Better (industry standard for new equipment) | Limited (used less in new designs) |

Conclusion

The choice between LC and SC connectors depends on your specific needs:

- Space constraints? Choose LC.

- Durability concerns? Choose SC.

- Working with existing equipment? Match what you already have.

- Building new? LC provides more future flexibility.

Remember that both connector types are proven, reliable options with excellent performance when properly installed and maintained.

Need Help Deciding?

Our fiber experts can help you choose the right connector type for your specific application. Whether you’re building a new network or upgrading an existing one, we’ll help you make the right choice.

Contact us today to discuss your fiber connectivity needs!

FAQS

Can I connect an LC to an SC connector?

Yes, with an LC-to-SC adapter cable or hybrid adapter. These are readily available and work well for transitions between different connector types.

Which connector has better performance?

When properly installed, both provide excellent performance with typical insertion loss under 0.3dB. The connector type doesn’t significantly impact signal quality.

Are LC and SC connectors available for both single-mode and multi-mode fiber?

Yes! Both come in single-mode (typically with blue or green housings) and multi-mode versions (typically with beige, aqua, or orange housings).

How do I identify LC and SC connectors visually?

- SC: Square, boxy shape, push-pull connection

- LC: Small connector with latch (looks similar to a telephone connector)

Can I install these connectors myself?

Yes, but it requires specialized tools and training. Pre-terminated cables are recommended for DIY installations.